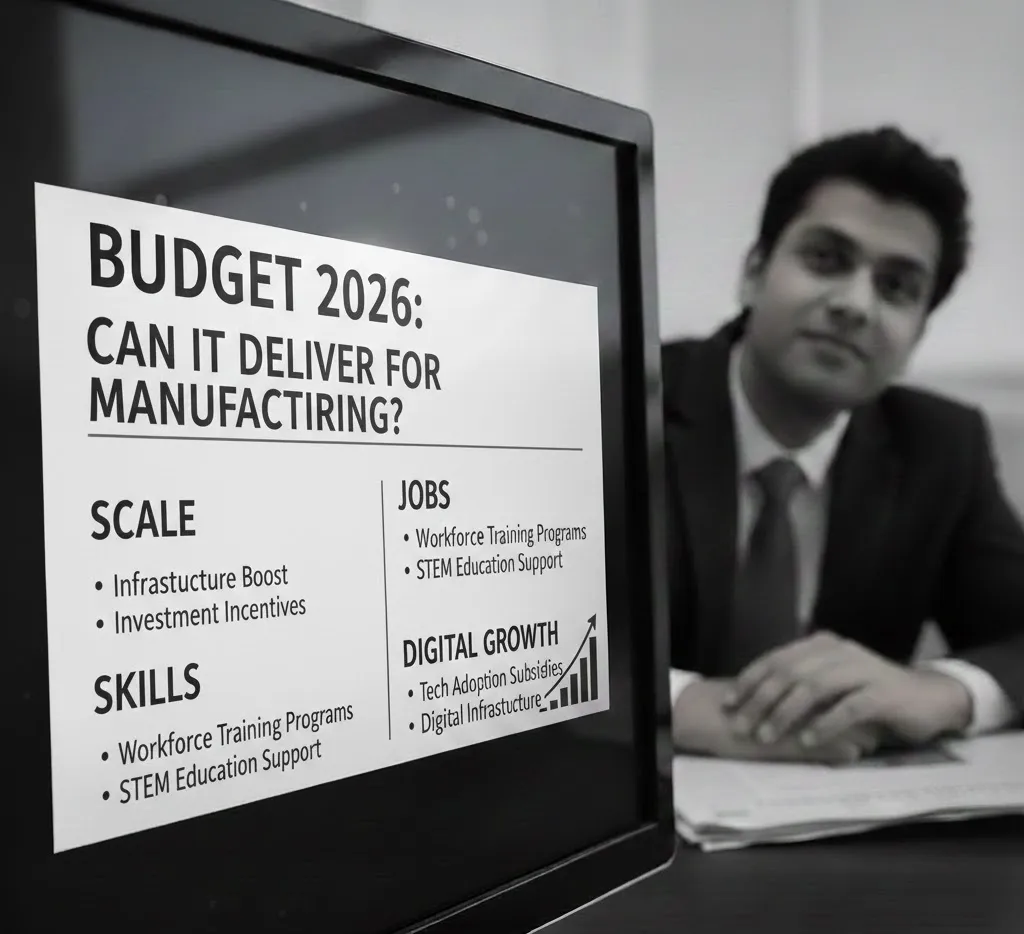

Can Budget 2026 Drive Scale, Skills, and Digital Growth in Manufacturing?

As India moves closer to the Union Budget 2026–27, the manufacturing sector has emerged as a key area of focus. Industry experts believe the coming year will be crucial in advancing India’s ambition to become a global manufacturing hub, with policy support, digital adoption, and skill development seen as top priorities.

Manufacturing gains policy momentumIndia’s manufacturing sector received a strong policy push in FY 2025–26, reinforcing its role as a major driver of economic growth. Rajesh Mehra, Director and Promoter at Jaquar Group, says the shift in government strategy has already begun delivering results. He notes that the transition from the National Manufacturing Policy to the National Manufacturing Mission marked a move from intent to execution, with greater emphasis on ease of doing business, scalability, and quality-led growth.

According to Mehra, this policy momentum has helped expand production hubs across the country and strengthened the foundations of the Make in India programme, moving India closer to a self-reliant manufacturing ecosystem.

Budget 2026 seen as a critical opportunityLooking ahead, Mehra believes manufacturing will be central to India’s next phase of growth. With the sector expected to contribute nearly 25% of GDP by 2027 and approach the $1 trillion milestone, sustained focus on reforms such as production-linked incentive (PLI) schemes and Make in India will be essential. He adds that continued policy support can deepen domestic value addition, attract fresh investments, and generate high-quality employment.

Global challenges persistDespite the positive momentum, global headwinds remain a concern. Jitendra Nenavani, Assistant Professor – Operations at K J Somaiya Institute of Management, points out that geopolitical tensions and volatile raw material prices are creating pressure on manufacturers. These uncertainties, he says, could slow growth as the sector works toward its long-term targets.

Nenavani emphasises the need to move beyond incremental improvements and focus on strategic execution in a few critical areas. Strengthening the impact of existing initiatives such as PLI, Ease of Doing Business, and Make in India will be key to sustaining momentum.

Digital adoption and skill development in focusDigitisation, particularly among MSMEs, remains one of the most pressing needs. Nenavani notes that MSMEs form the backbone of India’s manufacturing ecosystem and must adopt advanced technologies such as artificial intelligence and blockchain to improve efficiency, quality, and supply chain responsiveness. Targeted government support for digital adoption can help reduce dependence on legacy systems and enhance global competitiveness.

Equally important is the availability of skilled manpower. A well-trained workforce can lower training costs, accelerate technology adoption, and boost productivity. Nenavani stresses that sustained investment in education and training institutions is critical to bridging the gap between industry requirements and workforce capabilities.

With manufacturing poised to play a larger role in India’s economic growth, Budget 2026 is being closely watched. Experts agree that focused reforms, support for innovation, and continued investment in skills and digital infrastructure can help build a strong, sustainable, and globally competitive manufacturing sector in the years ahead.